Get A Free Legal Consultation

- We fight to maximize your results

- Many clients get results in as few as 90 days

- No out-of-pocket costs for you or your family

Aircraft mechanics are indispensable to our country’s military and commercial aircraft industries. Mechanics who were involved in the repair and overhaul of aircraft between the 1930s and 1990s were at risk of exposure to dangerous asbestos materials, and consequently, terrible diseases such as lung cancer and mesothelioma.

The risk of asbestos exposure for today’s mechanics is minimal, but may be a concern if the aircraft in need of repair was manufactured before the 1990s and still contains asbestos products. Exposure to asbestos can cause serious illnesses like the aggressive cancer mesothelioma.

Call (800) 326-8900 now to see if our asbestos attorneys can help your family secure compensation for mesothelioma. It costs nothing to speak with us.

Whether serving onboard a Navy carrier, or working at an Air Force Base, airport, or manufacturing facility, an aircraft mechanic’s work environment may have subjected him or her to significant asbestos exposure.

Spending most of their time in shops and hangers, mechanics often worked or stood shift next to other tradesmen as they maintained and repaired equipment containing hazardous asbestos materials.

The replacement of asbestos-containing brake pads was a particularly dusty, hazardous, and all too common duty of these mechanics. They would also handle asbestos-containing packing and gaskets in engines and other parts of the aircraft.

Further tasks associated with asbestos exposure risk include the installation of insulation around engines and electrical components.

Asbestos was a go-to material for the production of aviation products because of its heat resistance, durability and affordability. These qualities made it ideal for protecting aircraft components from fire and other sources of heat.

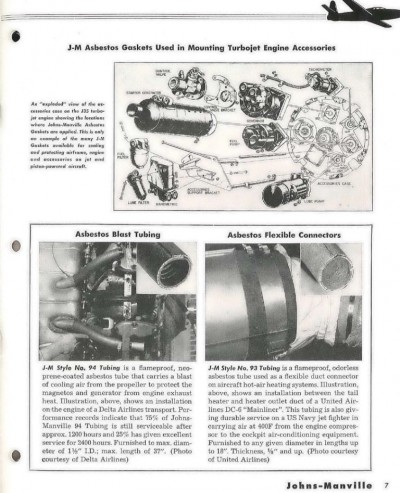

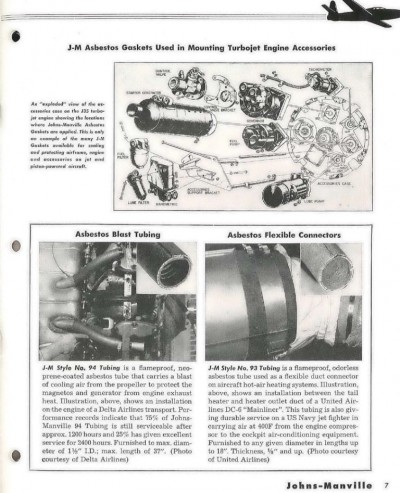

While the list of asbestos companies who knowingly exposed aircraft mechanics to asbestos is quite long, one of the most well-known is the Johns Manville Corporation.

Founded in 1858, Johns Manville produced a variety of asbestos products ranging from roofing and insulation to gaskets and cement.

Prior to the 1980s and 1990s, asbestos was found in several aircraft components and equipment used to repair aircraft may also have contained asbestos. For example, aerospace adhesives and epoxies, used as structural bonding agents between aircraft pieces or for filling dents and surface imperfections, may have contained the dangerous toxin.

As a leading national mesothelioma law firm, Simmons Hanly Conroy has worked to represent mesothelioma victims and their families for over 20 years.

Our mesothelioma lawyers are committed to pursuing justice for mechanics who were exposed to asbestos on the job. We treat our clients with the respect and personalized attention they deserve.

If you believe you or a loved one has been experiencing mesothelioma symptoms related to mechanics’ asbestos exposure, please fill out the form below to schedule a free legal consultation with one of our experienced mesothelioma lawyers.